Cleanup Operations

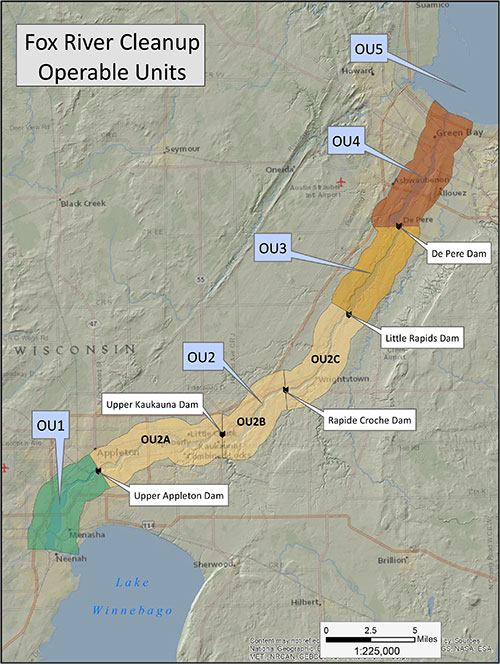

Sampling and studies on the Lower Fox River started in the early 1970s. These studies indicated that sediment contaminated with polychlorinated biphenyls (PCB) was deposited along the entire length of the river, but primarily in OU1, OU3, OU4 and OU5. The majority of sediment dredged from the river was in OU4.

Operable Units

For the cleanup operation, the Lower Fox River was divided into five Operational Units (OUs) based on its physical and geographical characteristics:

- OU1: from Little Lake Butte des Morts to Appleton Dam

- OU2: from Appleton Dam to Little Rapids Dam

- OU3: from Little Rapids Dam to De Pere Dam

- OU4: from De Pere Dam to the mouth of the bay of Green Bay

- OU5: the bay of Green Bay

Remedial Action Objectives (RAOs)

Records of Decision (RODs) are governing documents issued by the Environmental Protection Agency (EPA) for the project. The RODs define four Remedial Action Objectives (RAO) for the Lower Fox River cleanup:

RAO 1: Achieve, to the extent practicable, surface water quality criteria for PCBs throughout the Lower Fox River and Green Bay.

RAO 2: Protect humans who consume fish from exposure to contaminants that exceed protective levels (achieve safe exposure for recreational and high-intake fish consumers).

RAO 3: Protect ecological receptors from exposure to contaminants above protective levels (achieve safe ecological thresholds for fish-eating birds and mammals within 30 years following remedy completion).

RAO 4: Reduce transport of PCBs from the Lower Fox River into Green Bay and Lake Michigan (reduce loading to Green Bay and Lake Michigan comparable to loading from other Lake Michigan Tributaries).

Full-scale active remediation of the Lower Fox River began in 2004 in OU1 and has since moved north and downstream toward the bay of Green Bay (OU5). Active cleanup work was completed in 2020.

Demonstration Projects

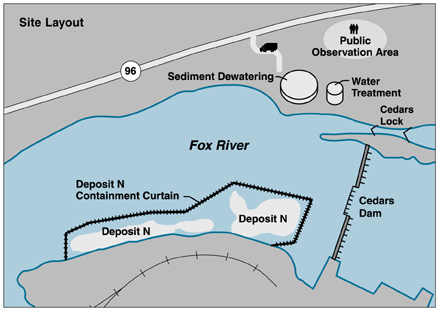

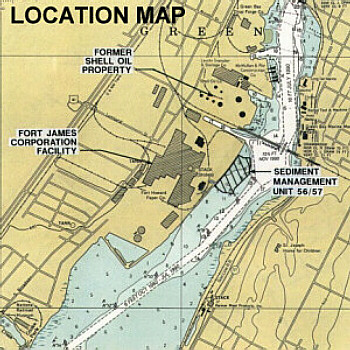

Two demonstration projects were completed on the Lower Fox River to evaluate for full-scale remediation: Deposit N (upstream at the village of Kimberly) and Sediment Management Unit (SMU) 56/57 (downstream of the De Pere Dam and adjacent to Georgia Pacific's west facility).

Deposit N

The three-acre Deposit N project is in OU2 and had a targeted cleanup of 11,000 cubic yards (cy). It was small enough to clean up quickly, while large enough to understand how the remediation could be applied in other areas of the river. It had an average concentration at 45 parts per million (ppm). Dredging of this area took place from 1998 – 1999.

SMU 56/57

The nine-acre area SMU 56/57 project site is in OU4 and had a targeted cleanup of 80,000 cy of sediment. This area had an average PCB concentration of 53 ppm and contained one of the highest single PCB concentrations on the river known at the time (710 ppm). The remediation of this area took place in 1999 – 2000.

Cleanup Summary

OU1, the upriver section known as Little Lake Butte des Morts, runs from Lake Winnebago to the Upper Appleton Dam. Active remediation took place in this OU from 2004 to 2009. In the six years of remedial action, 372,000 cubic yards of sediment were removed and 114 acres were capped. Monitoring of these caps, along with long-term monitoring of fish and water, will continue for decades.

Remediation for OUs 2-5 began in 2009 and active remediation was completed in 2020.

A combination of dredging, capping and sand covering was the selected remedy for OU3-4 and parts of OU5 at the mouth of the Fox River into Green Bay, where over six million cubic yards of sediment were dredged and about 850 acres capped or sand-covered. See the long-term monitoring section for information on cap monitoring and maintenance.

Monitored natural recovery was the selected remedy for OU2 and most of OU5. Deposit N was an exception to the monitored natural recovery remedy in OU2 since it was dredged as a demonstration project.

The Bureau of Remediation and Redevelopment Tracking System (BRRTS) on the Web (BOTW) provides a detailed background on the State Closure of the site and contains the OU1 PCB Cleanup BOTW Site File. To view the file:

- Launch BOTW.

- Using the Search Criteria table, enter 02-71-582406 in the BRRTS No. box for OU1 and 02-450582407 for OUs2-5.

- Click the "Search" button to review documents for the site including a PDF of the Continuing Obligations (CO) Packet.

Phases 1 And 2

"Phase 1" refers to an expedited cleanup effort conducted prior to the start of the full OUs 2-5 cleanup project due to extremely high PCB concentrations in sediments. The Phase 1 area was located on the west side of the river just downstream of the De Pere Dam and had the highest PCB concentrations in the river (up to 3,000 ppm). Dredging was performed in 2007 to remove 132,000 cubic yards of sediment and approximately 20% of this material needed to be disposed at a hazardous waste landfill in Michigan. The Phase 1 area remedial dredging was completed during "Phase 2" of the Fox River PCB Cleanup, which refers to the full cleanup effort in OUs 2-5.

Green Bay MGP

The Green Bay Manufactured Gas Plant (MGP) site was located at the mouth of the East River, between the WPS Corporation and the Georgia Pacific Day Street Facility. The site was broken into two sediment management zones, the South Focus Area (SFA) and the North Focus Area (NFA), and remediation was completed in 2018 and 2019, respectively. Although MGP waste was not the focus of the PCB cleanup, these contaminants were removed in conjunction with and under the PCB Superfund Site authority. The following summary reports provide an overview of the targeted cleanup.

Water Treatment

OU-1

The first phase of the Fox River cleanup took place in Little Lake Butte des Morts (OU-1), where hydraulic dredges were used to remove 370,000 cubic yards of contaminated sediment. This method of dredging generates large volumes of carriage water; that is, the surrounding water that is suctioned along with the sediment and carried through the discharge pipeline. The water and sediment slurry were pumped to the west shore of Little Lake Butte des Morts and into giant tubes made from a woven polypropylene textile. These "geotubes" safely captured the sediment but allowed water to pass through, draining and dewatering the sediment over time under the natural force of gravity.

Drainage from the entire geotube field was continually captured using a sump system and then pumped to holding tanks, which allowed control over the flow rate as the water entered a treatment system constructed at the site. Clarification of the wastewater via polymer-induced coagulation of clay-size particles was followed by sand and carbon filtration to ensure the capture of any remaining contaminated particulates before the water was tested, then pumped back to the river.

OU-3 Through OU-5

Downstream at OUs 3, 4 and 5, hydraulic dredges were also used to auger and siphon contaminated sediment from the riverbed. But unlike at OU-1 where dredge material was passively dewatered, it was necessary to actively dewater the sediment dredged from the downstream OUs due to the enormous volume of contaminated sediment being removed and the limited space available for dewatering and water treatment. The dredged slurry was pumped through floating pipelines to a large facility built specifically for the Fox River cleanup. This sediment processing facility was constructed in 2008 and was located on the west side of the river immediately north of the Georgia Pacific paper mill. The 247,000-square-foot building housed all the equipment necessary to dewater the sediment and treat the carriage wastewater.

The piped slurry was sent directly from the dredges into the processing facility where it was pumped over screens to capture large debris such as rocks, wood waste, cans, etc. The slurry then entered large conical chambers where the incoming water pressure created a vortex that allowed heavier sediment grains (sand) to be separated from the silty mud. This sand was conveyed to a designated area outside of and behind the building, where it was stockpiled and tested for PCBs then later hauled away to be used in nearby road construction projects.

After the sand separation, the silt slurry was pumped into a series of large filter-plate presses, which squeezed the water from the sediment by applying 200 pounds of pressure (psi) to the filter plates. After compression, the plates opened and the dry sediment “cake” dropped onto a conveyor and was transferred to a separate garage within the facility, where it was stockpiled and then loaded into trucks for disposal at a licensed landfill.

All of the wastewater that entered or was generated in the sediment processing facility was treated using a state-of-the-art treatment plant designed specifically for the Fox River cleanup. The plant operated 24 hours a day and each step of the water processing was monitored and controlled around the clock. Like at OU-1, water treatment relied on the separation of solids through polymer application and clarification, then sand and carbon filtration and passage through 10-micron fabric filters before finally being discharged back to the river. All told, over nine billion gallons of water were treated in this facility before it was decommissioned in 2020 after the final PCB dredging season was complete.

Please see the following video to get a better understanding of the enormity and complexity of sediment processing and water treatment:

Boskalis Environmental & Spri – Green Bay Fox River Clean Up