Ethylene Oxide

Ethylene oxide (EtO) is a flammable, colorless gas used to make other chemicals. It is necessary for the production of a range of products, including antifreeze, textiles, plastics, detergents and adhesives. Ethylene oxide also is used to sterilize equipment and plastic devices that cannot be sterilized by steam, such as medical equipment.

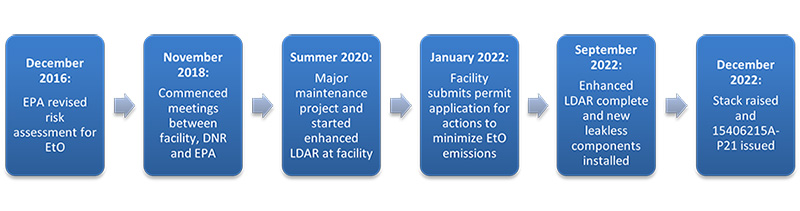

Ethylene oxide in the air can come from different types of sources, including industries such as chemical manufacturers and sterilizers. In December 2016, the Environmental Protection Agency (EPA) revised the risk assessment for EtO emissions to be more stringent. Studies show that long-term exposures to EtO are associated with an increased risk of certain types of cancer, including breast cancer and cancer of the white blood cells, including non-Hodgkin lymphoma, myeloma and lymphocytic leukemia.

Evonik Corporation

Evonik Corporation, located at 337 Vincent St. in Milton, WI, is a chemical manufacturing plant. Previously, the facility was also known as Air Products Performance and Tomah Products. This location has held an active air permit since 1990. The DNR inspected Evonik in May 2018 and found no evidence of noncompliance.

Evonik manufactures specialty chemicals, primarily sold as components to formulators and commonly known as surfactants. Surfactants are compounds that lower the surface tension between two liquids, a liquid and a gas or a liquid and a solid. The resulting products are used as components in household, industrial and institutional cleaners as well as mining, roof coatings, asphalt and other industrial applications. This facility is regulated under Wisconsin's state air toxics rule (NR445) [exit DNR], and the state has worked with this location since 2010 to reduce emissions and obtain the best annual emission estimates for EtO.

Obtaining the best annual emission estimates for EtO is challenging. Most calculated emissions are not from stacks or vents but are released from over 2000 fugitive components such as valves, flanges, connectors, pumps and seals.

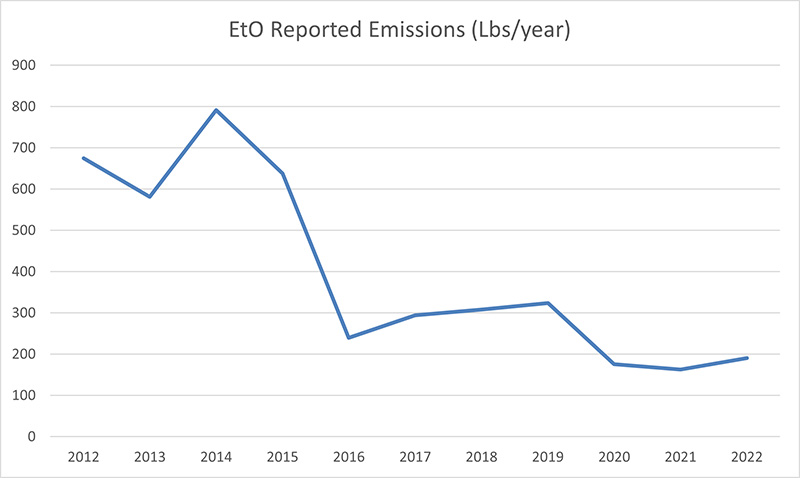

Estimates of EtO emissions from Evonik Materials Corporation have dropped significantly over the last 10 years due to a systematic verification of emissions calculations.

Since the EPA’s 2016 revision of the EtO risk assessment, the DNR has worked with Evonik Corporation to implement modifications to reduce emissions and minimize the exposure of EtO to the surrounding community. Evonik Corporation completes monthly enhanced Leak Detection and Repair (LDAR) monitoring of each component on site that has the potential to emit EtO and takes corrective action when concentration readings as low as 100 parts per million (ppm) are identified. Evonik has raised the primary stack emitting EtO at the facility to 76 feet above ground to reduce emission concentrations. The corporation also reduced the number of valves and connections by replacing those components with new leakless components.

These three voluntary actions (enhanced LDAR, raised stack, fittings replacement) were made legally binding within the air pollution control operation permit number 15406215A-P21, issued on Dec. 7, 2022.

Background Information

- What is ethylene oxide? [exit DNR]

- Evonik State Air Permits and Annual Emission Inventories

- 2014 National Air Toxics Assessment (NATA) [exit DNR]

- U.S. EPA Office of Inspector General Report [exit DNR]

- Frequent Questions on Ethylene Oxide [exit DNR]